Materials

|

Pipe / Tube |

Materials |

Grade |

|---|---|---|

|

Seamless Pipe / Tube |

SUS316L SUS316L Double Melt (VIM+VAR) Hastelloy |

EP / BA |

|

Welded Pipe / Tube |

SUS 304 SUS 316 SUS 316L Hastelloy |

EP / BA / MP / AP |

Surface Roughness

|

Designator |

Rmax (Ry) |

Internal (Ra) |

External (Ra) |

|---|---|---|---|

|

BA |

≤ 3.0 ㎛ |

≤ 10 μinch |

≤ 30 μinch |

|

EP |

≤ 0.7 ㎛ |

≤ 5 μinch |

Testing

|

He Detector Leak |

Detection sensitivity |

1 x 10-9 torr.l/sec |

|---|---|---|

|

Measruing instrument |

ALCATEL |

|

|

Pressure |

1 MPa (10 ㎏f/㎠) |

|

|

Airtightness |

0.7 MPa (7 ㎏f/㎠) |

|

|

Particle Counter |

Detection sensitivity |

0.1 ㎛ |

|

Measruing instrument |

Lightnouse |

|

Ordering Information

A

ASFLOW

B

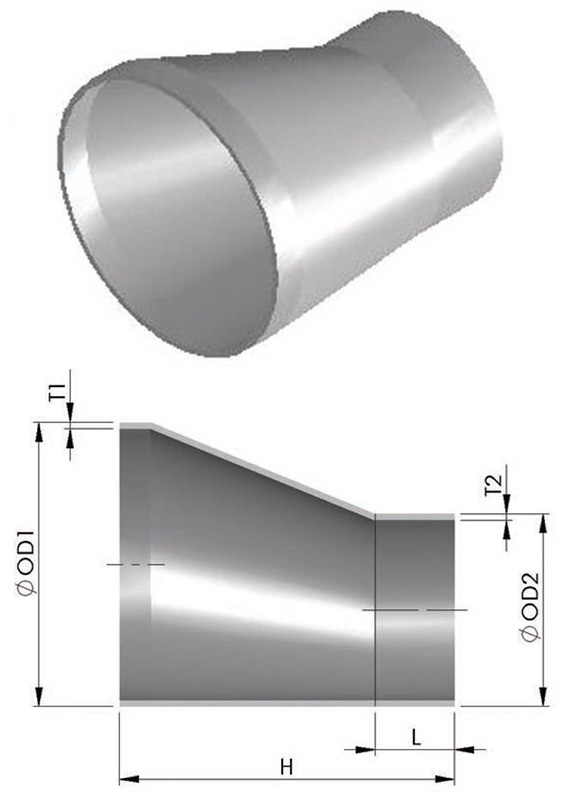

Classifications

ER

Product

04

Size

|

Brand |

Classifications |

Product |

Size |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

ASFLOW |

B |

Bend Fittings |

ER |

ECC Reducer |

04 |

1/4” |

20 |

1-1/4” |

48 |

3” |

|

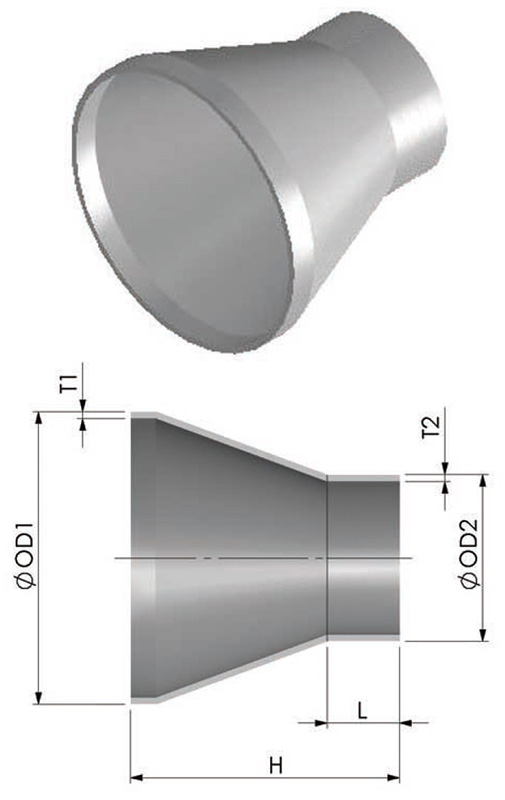

CNR |

CON Reducer |

06 |

3/8” |

24 |

1-1/2” |

64 |

4” |

|||

|

08 |

1/2” |

32 |

2” |

80 |

5” |

|||||

|

10 |

5/8” |

40 |

2-1/2” |

96 |

6” |

|||||

|

12 |

3/4” |

* Pipe Size : __A |

||||||||

|

16 |

1” |

|||||||||

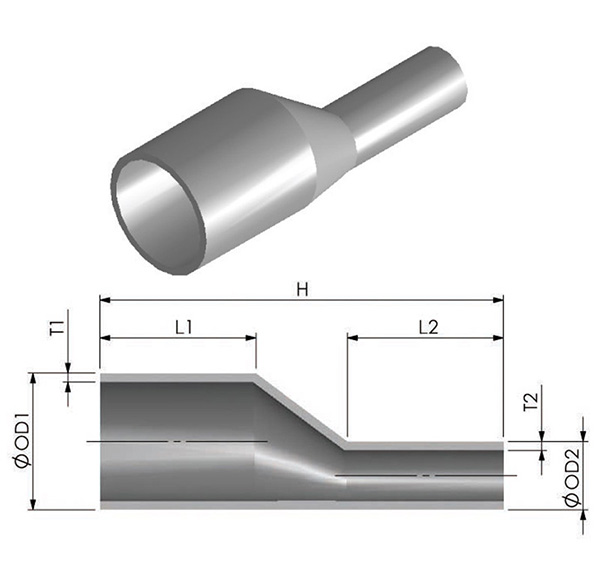

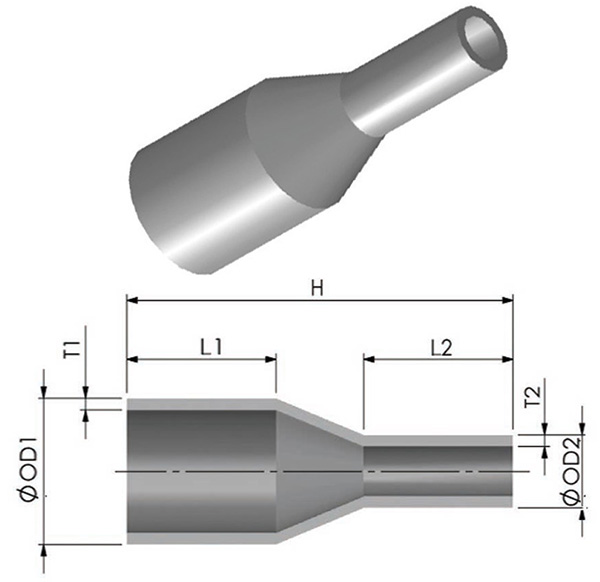

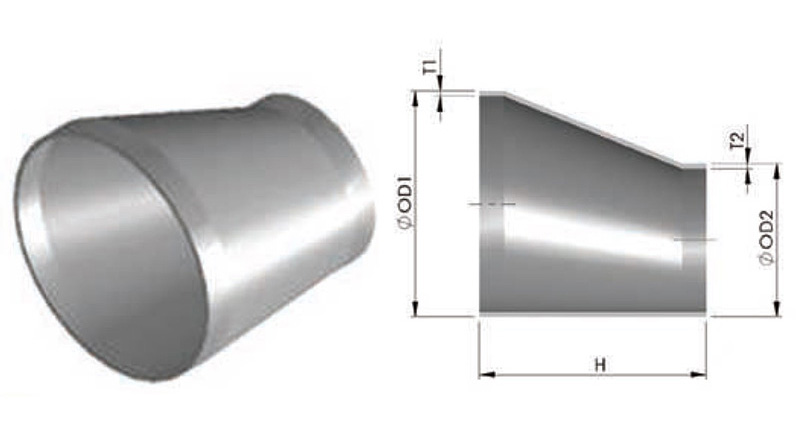

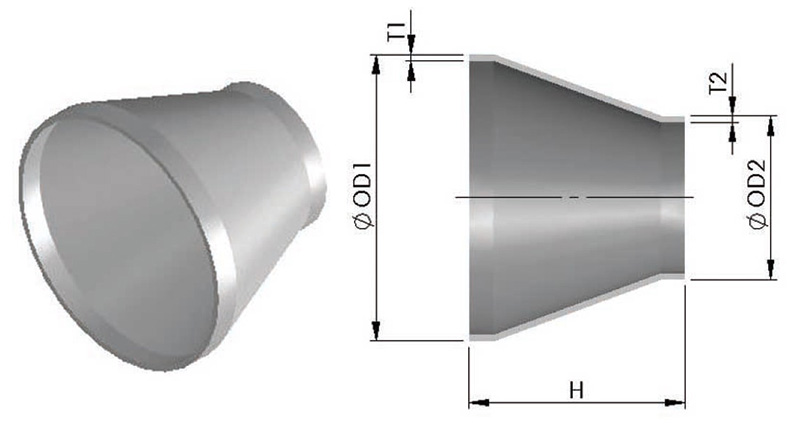

Dimension

Auto Welding

Manual Welding

Manual Welding of Large Diameter side

Auto Welding – Tube Size

(unit = ㎜)

|

OD1 |

OD2 |

H |

OD1 |

OD2 |

H |

|---|---|---|---|---|---|

|

1/4″ |

|

60 (70) |

1-1/2″ |

1-1/4″ ~ 1/4″, 25A ~ 8A |

85 (125) |

|

3/8″ |

1/4″ |

60 (70) |

2″ |

1-1/2″ ~ 1/4″, 40A ~ 8A |

95 (130) |

|

1/2″ |

3/8″, 1/4″ |

60 (75) |

2-1/2″ |

2″ ~ 1/4″, 50A ~ 8A |

105 (140) |

|

5/8″ |

1/2″ ~ 1/4″, 8 |

70 (90) |

3″ |

2-1/2″ ~ 1/4″, 50A ~ 8A |

110 (165) |

|

3/4″ |

5/8″ ~ 1/4″, 10A, 8A |

75 (100) |

4″ |

3″ ~ 1/4″, 80A ~ 8A |

130 (175) |

|

1″ |

3/4″ ~ 1/4″, 15A ~ 8A |

75 (105) |

5″ |

4″ ~ 1/4″, 100A ~ 8A |

180 (230) |

|

1-1/4″ |

1″ ~ 1/4″, 20A ~ 8A |

75 (120) |

6″ |

5″ ~ 1/4″, 125A ~ 8A |

200 (250) |

* Please refer to “Pipe & Tube” products on this homepage for outside deamenter(OD), thickness(T) and length(L) of straight end length.

Auto Welding – Pipe Size

(unit = ㎜)

|

OD1 |

OD2 |

H |

OD1 |

OD2 |

H |

|---|---|---|---|---|---|

|

8A |

1/2″ ~ 1/4″ |

60 (80) |

50A |

2″ ~ 1/4″, 40A ~ 8A |

95 (140) |

|

10A |

1/2″ ~ 1/4″, 8A |

70 (90) |

65A |

3″ ~ 1/4″, 50A ~ 8A |

105 (165) |

|

15A |

3/4″ ~ 1/4″, 10A, 8A |

75 (100) |

80A |

3″ ~ 1/4″, 65A ~ 8A |

110 (170) |

|

20A |

1″ ~ 1/4″, 15A ~ 8A |

75 (105) |

100A |

4″ ~ 1/4″, 80A ~ 8A |

180 |

|

25A |

1-1/4″ ~ 1/4″, 20A ~ 8A |

75 (120) |

125A |

5″ ~ 1/4″, 100A ~ 8A |

250 |

|

32A |

1-1/2″ ~ 1/4″, 25A ~ 8A |

85 (125) |

150A |

6″ ~ 1/4″, 125A ~ 8A |

260 |

|

40A |

1-1/2″ ~ 1/4″, 32A ~ 8A |

95 (130) |

200A |

6″ ~ 1/4″, 150A ~ 8A |

280 |

* Please refer to “Pipe & Tube” products on this homepage for outside deamenter(OD), thickness(T) and length(L) of straight end length.

Manual Welding – Pipe Size

(unit = ㎜)

|

OD1 |

OD2 |

H |

OD1 |

OD2 |

H |

|---|---|---|---|---|---|

|

100A |

|

– |

200A |

150A, 125A |

152.4 |

|

125A |

100A |

127 |

250A |

125A, 150A, 200A |

177.8 |

|

150A |

125A |

139.7 |

300A |

125A, 150A, 200A, 250A |

203.2 |

* Please refer to “Pipe & Tube” products on this homepage for outside deamenter(OD), thickness(T) and length(L) of straight end length.

Manual Welding of Large Diameter side –

Automatic Welding of Branch Pipe/Small Diameter sides (with Straight Length end) Fittings

(unit = ㎜)

|

OD1 |

OD2 |

H |

OD1 |

OD2 |

H |

|---|---|---|---|---|---|

|

100A |

|

– |

250A |

150A, 125A |

250 |

|

125A |

100A, 80A, 65A, 50A |

190 |

200A |

270 |

|

|

150A |

125A, 100A, 80A, 65A |

205 |

300A |

150A, 125A |

280 |

|

200A |

150A, 125A, 100A |

220 |

200A |

300 |

* Please refer to “Pipe & Tube” products on this homepage for outside deamenter(OD), thickness(T) and length(L) of straight end length.